From preventive maintenance to complete rebuild : trust Drekan’s Experience !

IN-SHOP ELECTRIC MOTORS & GENERATORS SERVICE

Drekan service centers can handle all your industrial AC & DC electric motor and generator repairs, everything from small, fractional HP, low-voltage units (<690V) to assets weighing 80 tons and with a rating of 15kV.

We implement a quality management system that aligns all our engineering resources, skilled technicians, technologies and proprietary rewinds. We provide service for:

• AC induction motors – squirrel cage & wound rotor

• AC synchronous motors – brushless & slip ring

• AC generators – hydro, wind turbine, steam turbine

• DC motors – permanent magnet, series, shunt, compound

• Specialty motors – vertical, hermetic, nuclear, explosion-proof, servo

• Voltage ratings from low voltage to 15,000 VAC / 1,000 VDC

• HP ratings from fractional to 50,000+ HP

Small AC Motors repair or rewind

Drekan has opened small electric motor repair shops within many of our local service centers. These outlets typically focus on up to 690 VAC low-voltage units for common industrial applications and manufacturing facilities. Dedicated repair technicians run these small motor shops that prevent them from moving back and forth between large and small motors. They make fast repair-or-replace decisions, using standardized work procedures and processes designed to reduce the use of the crane, work truck and cart interchange.

This cuts our lead times substantially and allows for cost-competitive repairs for:

• IEC motors

• Arbor motors

• Gear motors

• Servo motors

• Spindle motors

• Small definitive purpose contactors, non-stock motors

Drekan small motor repairs cost less than the purchase of a new motor and come with a Drekan warranty. If you’re interested in reducing your overall plant maintenance and small motor repair costs, talk to your regional DREKAN sales representative or contact us.

Industrial & Traction DC Machines repair or rewind

The complexity of industrial or traction DC motor repairs requires highly skilled and experienced craftsmen. With superior quality materials, our wrapping machine meets today’s high operating demand standards. Used to working on Shunt, Series, Compound, and Traction motor with ratings between 90V and 850V, our teams of technicians are highly qualified to work on your motors.

Thanks to the integration of Nelco Commutators into the group in 2016, Drekan is one of the rare independent motor repair company able to design, manufacture or repair DC commutators. Nelco manufactures more than 10,000 molded or VRings commutators each year for repairers and manufacturers around the world.

Some of well-known motors at Drekan:

• ABB – DMA, DMB and DMI industrial DC motors

• Leroy Somer – LSK industrial DC motors

• CEM G500, G630, G800 industrial DC motors

• D29 to D77 electromotive/progressrail traction DC motors

• Alstom transport traction DC motors

• GE761, 763, etc traction DC motors

And many more …

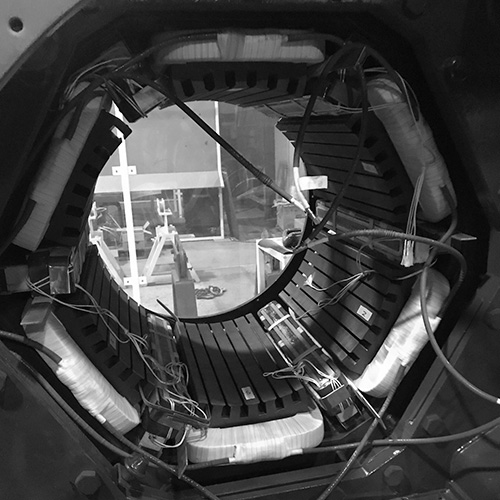

Large AC/DC Machines repair or rewind

Drekan gives you more ways to test, repair, rewind, rebuild or reverse engineer large or extra-large motors and generators. We have extensive experience in the removal and installation of large, highly engineered applications, plus comprehensive testing, heavy-duty lifting, high-voltage VPI rewinds and B-stage hard coils.

Our large and extra-large resources include:

• 80-ton lift capacity

• 3m VPI tank – 15KV resin

• No-load testing up to 20.000 HP

• Load testing up to 7.500 HP

• Bake Oven 3m x 4m x 8m

• Foreign Material Exclusion (FME) Winding

Submersible water pumps repair or rewind